Last articles

Transmissions info

About transmissions

Transmission general data

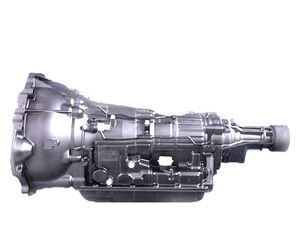

AS69RC is a 6-speed A/T produced by Aisin and initially

intended for Ram 3500 HD. This gearbox took place of AS68RC in chassis cab

modifications for 2013. It transmits the drive torque equal up to 1150 Nm. In

terms of design this gearbox resembles AS68RC. AS69RC is large-sized and more

reliable than AS68RC and 68RFE. AS69RC has 3 planetary gear sets, 1 overrun

clutch, and electronically-controllable gear switching and the converter

clutch.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type6ATRWD/AWD1150136,8Mopar ASRC

Technical issues and repair guidelines

Specialists assume that the following service procedures are required for this transmission: change ATF every 30 thousand miles or 2 years, replace gearbox filter every 60 thousand miles or every 4 years. Starting from 2014 the modification AS66RC appeared to replace AS69RC in Dodge Ram trucks.

How to repair this transmission (Videos)AS69RC Teardown Part

Transmission general data

4N71B 4-speed automatic transmission 4N71B was

produced in 1984 for rear wheel drive Nissan 300ZX.This transmission is a

successor of very famous 3-speed modification 3N71B. Since 1989 this transmission was modified for Mazda 929 under the name N4A-EL. In 2000 4N71B was used as a basis for updated JR401E, which is used with 3-liter engines V6.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type4ATRWD2807AT-Matic J

Technical issues and repair guidelines

This transmission appears in repair services very rarely. Due to its simple design specialists usually just need to replace worn-out spare parts and friction clutches to bring this transmission back to life.

How to repair this transmission (Videos)Valve Body Shift Kit Installation

Instruction manuals and useful linksLink typeSourceDescriptionpdfwaghornswood.net.nzRepair manual E4N71Bpdfshinseiauto.comScheme 4N71B

Transmission general data

Flashomatic

automatic gearbox was also named as BW8 (1956-66)/BW12 (1956-71). This gearbox had

been actively installed on different models of Packard, Rambler, Studebaker

during 1956-71.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type3ATRWD9,84,2ATF Type F

This transmission is considered to be quite durable due to its iron case. The BW-12 was installed on some Ford vehicles in 1973-74.It is a hydraulically controlled RWD gearbox. This gearbox resembles Ford-O-Matic manufactured in 3 different case sizes used from 1951 until 1968) and FMX gearbox (released in 1968), but few of the parts are interchangeable.

Transmission general data

The

THM425 (and later 325) is a 3-speed automatic gearbox designed and released by

GM. The structure of the THM425 is based on the THM400; most spare parts in

these gearboxes are directly interchangeable and some others can be adjusted

with the help of slight modifications. The THM425 was designed for Oldsmobile

Toronado and Cadillac Eldorado.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type3ATRWD12,36Dexron II

More lightweight gearbox THM325 took the

place of the THM425 in both car ranges in late 1978. Since 1979 and later longitudinal

engine FWD cars have been equipped with the THM325. The THM325 was upgraded to

THM325-4L with an overdrive added in 1982, but all cars with this gearbox

switched to more-common transverse engine mounting in 1986.

How to repair this transmission (Videos)TH-400 rebuild part 1TH425 Governor Gear RemovalTH400 Rebuild: Governor

Transmission general data

The automatic gearbox THM250 is based on the

THM350. This gearbox was released in 1974 and was applied in Chevrolet cars.

The THM250 was developed and designed by GM as a part of Turbo Hydra-Matic family

of automatic gearboxes. When taking into consideration the internal structure

of the gearbox, the THM250 is very similar to THM350, apart from the

intermediate clutch package with a band adjuster.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type3ATRWD9,55,6Dexron II

Generally, the THM250 was attached to small displacement engines. In 1976 this gearbox was taken out of production and was replaced by the light-duty THM200 transmission. However, the THM250 reemerged in 1979 as the THM250-C as a result of numerous issues withTHM200/200C. The 250C version had a reduced weight thanks to the use of a central gear shell applied the THM350, but with three holes to decrease flywheel mass and the low/reverse piston with eight notches.

Instruction manuals and useful linksLink typeSourceDescriptionpdfoldcarmanualproject.comRepair manual THM250

Transmission general data

CVT VT1-27T Mini (or general name for this family - VT1F) found application on Mini BMW. In addition to Mini, this CVT was offered to Volvo, Land Rover, Hyundai, but this transmission rarely comes to repair services and its hard to find spare parts for repair of this CVT. The following modification CVT VT2 was a budget-friendly solution. This CVT had been offered to many automakers from 2009 to 2013.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type∞CVTFWD1507,64,3Esso EZL799

Technical issues and repair guidelines

This CVT has a typical design (with a solid reserve on transmission components) with a push belt and does not require repair for many years, except replacement of ATF and filter, and later – replacement of Bosh belt. This CVT was developed specially for BMW mini.

Settings of the VT1 control unit are adjusted for preserving expensive cones at low speeds, when the belt and surfaces of cones operate closely to the limit. Cones have wear-resistant cover of operating surfaces with the use of space technologies can not be rebuilt and not supplied to the repair market. CVTs of this generation are very sensitive to the level of ATF, therefore the check of this parameter is very technology-savvy.

Rare overhauls with reassembly of spare parts, wear-out of which leads to pressure losses on friction elements and as a consequence their (frictions) wear-out require the repair kit of gaskets and seals. While maintaining these CVTs experienced specialists replace the filter and change ATF as often as possible to avoid time consuming search operations for spare parts. Simultaneously with change of fluid and filter replacement, it is recommended to check the belt for wear-out of the protector. If there are any suspicions about wear-out, it is better to replace the belt. Even slightly wornout belt increases the risk of slipping (metal-on-metal) in situations with usual "non-sporting" acceleration in order to outrun the truck ahead. Generally, this CVT is quite comfortable and “invincible” under the condition of proper care. It is one of the top CVTs on the market.

How to repair this transmission (Videos)Replacing Belt part 1Belt replacement pt2Mini Cooper CVT overviewZF VT1 CVT Transmission Stepper MotorRover - Service Insight - VT-1 Automatic TransmissionMini CVT transmission teardownMini CVT teardown test clipMini Cooper cvt adaptation

Transmission general data

The 722.8 transmission (CVT) has been produced since 2005 and mainly used on Mercedes А170. It is also installed on other cars of А series with engine capacity from 1.5 to 2.0 liters.

The design of this CVT is based on model patent CVT with the "push" belt produced by Bosch-Fondorn and the most expensive spare part – the belt itself. This CVT is the analog and competitor of a Japanese CVT JF011E.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type∞CVTFWD30076236.20

Technical issues and repair guidelines

Overhauls of old cars with this transmission usually require the kit of spare parts (gaskets and seals from Autoline) and the kit of friction components. Friction components are replaced quite often in the process of the transmission reassembly, because the 722.8 unit is removed together with the engine, and easily wornout frictions already have a negative impact on the clutch. Driving with worn rings and seals lead to oil starvation and premature burning of quite durable friction components.

The fluid in 722.8 should be changed timely together with filter. The fluid and its purity are critical for cones and belts of this CVT, therefore for old 722.8 units, it is recommended to add the fluid at every opportunity and check its level with a service gauge.

The electrical part always causes a lot of problems in Mercedes transmissions. The board was made by the partnering company of Mercedes and after the warranty period you can face such problems as contaminated fluid (metal dust) and overheating. Steel dust magnetized on sensors lead to their failure.The belt is another vulnerable place in this advanced unit. Mercedes used the belt with additional resource on durability and reliability for its CVT.

Shaft bearings are the first among hard parts to get out of order (like with Jatco CVTs) because of lateral dynamic loads. The end of shaft-cones service life means the end for the CVT unit itself. The lifespan of bearings is highly dependent on the fluid cleanness, and most importantly - on its operating temperature.

How to repair this transmission (Videos)Gearbox control unit sensor

Instruction manuals and useful linksLink typeSourceDescriptionwebactronics.euMercedes-Benz Temic VGS (722.8)pdfautogear.fiScheme 722.8

Transmission general data

The 5-speed automatic gearbox U250E is installed on all FWD and AWD vehicles produced by Toyota and Lexus with engine capacity from 2.5 up to 3.5 liters.

The whole range of U150 is more comfortable and economically viable (and high priced) alternative to "invincible" 4-speeds U140-U240. The 6-speed automatic gearbox U660 was produced in 2007 for Toyota Camry and Lexus car drivers who are more demanding of gear shifting process. The U150, 151 – can transmit a bit higher torque at low speeds than U250E. The U151F unit is intended for 6-cylinder full-wheel drive vehicles- RAV4, Highlander, Sienna.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type5ATFWD/AWD94Toyota Type T-IV

Technical issues and repair guidelines

Major repairs of U150-250 units almost always starts with the torque converter repair and spare parts replacement ( lockup).The set of pistons is also included in the typical list of spare parts for repair of this transmission. The pairs of firctions (steel disks in the Overdrive drum) is the first component to get burned in these units. The second spare part to be considered is burnt Direct clutch (happens if the vehicle continuously operates with burnt Overdrive frictions).

The kit of friction components is ordered as frequently as the Overhaul kit especially when repair specialists have to deal with gearboxes with burnt ATF. Early wear of the Overdrive friction clutch is linked to the design of the rear cover, which plays the backup role for this clutch cover (drum). The other common issue for majority of these automated gearboxes is related to problems with pump seals and axles. The pump bushing is usually ordered together with abovementioned spare components. The main symptom of the problem is the ATF leakage through the pump seal. The main cause of this problem is an aggressive driving style and a long-term driving with burnt torque converter clutch.

Electrics in U250-150

Problems with electrical parts in U250 and U151 gearboxes are often triggered by issues with the valve body.The valve body U250 (2002-2004) frequently could not maintain set parameters, old (massive) solenoids couldn’t cope with tasks, therefore the valve body wears rapidly. In 2005, the valve body was updated after replacement of solenoids (the valve body itself was left unchanged). Solenoids for valve bodies of U250 and U151 units ranges for different cars and selected according to VIN-code of the car.

Peculiarities of early repairs of U250 and U151 units are related to the fact that the “electric clutch” was widely used in 2000-th and engineers refused from the "full-proof" comcept and did not limit capacity of the driver related to the aggressive driving style, that may lead to burning of friction components and other elements.

How to repair this transmission (Videos)U151 Teardown

Instruction manuals and useful linksLink typeSourceDescriptionpdfwww.at-manuals.comRepair manual ECT U150Epdfwww.at-manuals.comRepair manual U150Epdfwww.at-manuals.comScheme U150Ewebwww.at-manuals.comSolenoid identification U150EpdfSonnaxValve Body Layout U151E/F, U250E pdfSonnaxVacuum test valvebody U151E/F, U250E

Transmission general data

The automatic 4-speed transmission B7TA was designed

by Honda specialists in 1996. It is intended for front-wheel drive Honda and

Acura vehicles.

This modification of

automatic transmissions can be installed on 6-cylinder engines with the

capacity not higher than 3.5 liters. In the process of operation this

transmission made a good impression. Due to its simple design, this

transmission is distinguished by its reliability and durability. The

maintenance service for this transmission is not complicated.

HONDA ODYSSEY 2.3L; V6 3.5L; Honda B7TA

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type4ATFWD7,12,9Honda Z-1

Technical issues and repair guidelines

After running 50 thousand kilometers it is required to change the oil with a filtering element. The car owner can perform this procedure by himself even with a limited experience in this field. B7TA has no planetary gears that allowed engineers to simplify the design of this transmission. It had a positive impact on the level of durability and reliability of this automatic transmission. It is not unusual, when well-timed maintenance and proper usage helps this transmission to cover 400 thousand kilometers without major repairs. Transmission specialists recommend warming up of the oil in this transmission in winter. It can be done the following way: shift the selector lever to the Drive position and hold the brake pedal depressed for about 30 seconds. This measure will help to warm up the transmission oil and prolong the trouble-free operation of the transmission. It should be also kept in mind that immediate accelerations after the start of the movement and gear-shifting in the manual mode may be harmful for the transmission.

The list of common problems with B7TA includes issues with rubber gaskets which lose their elasticity after running 100-150 thousand kilometers that leads to oil leakages. In this case the repair procedure lies in replacement of these gaskets.

How to repair this transmission (Videos)B7TA Transmission - Honda Odyssey

Instruction manuals and useful linksLink typeSourceDescriptionpdfdrive.google.comB7TA Manual

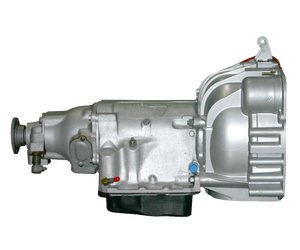

Transmission general data

The 6-speed automatic transmission AB60F (-Е – for rear drive) or AS68RC for Dodge RAM of the class extra heavy duty, Aisin name TB-68LS. This transmission was produced by Aisin Co since October of 2007 and paired with the engine V8 (5.7 liters) for 4WD SUVs such as Land Cruiser, Tundra, Sequoia, Lexus LX570.

This reliable 6-speed transmission with "invincible" design tested on rear-driven predecessors А760-960 and on 8-speed АА80Е released the year before (2006). The main competitive product of this transmission is ZF6HP32.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type6ATRWD/AWD68011,84,6Toyota WS

Technical issues and repair guidelines

Electrical components in this transmission is extremely sensitive to the transmission fluid status. The oil change requires specific knowledge and experience.

During the overhaul the following parts are ordered for reassembly:the kit of gaskets and seals as well as kit of frictions.Friction components in this transmission are not complex and serve reliably till the end of the transmission resource. Frictions are usually changed as a result of operation with worn-out rings, bushings and sealing. First of all the, clutch drum Forward (С1 gears 1-2-3-4) gets burnt. All overhauls of the AB60F unit still involve the torque converter repair with replacement of the lockup clutch, replacement of burnt clutch, replacement of the filter and full spare parts kit: seals and gaskets made of rubber and paper.

The valve body design is similar to the valve body of the А960Е transmission and it should be expected that typical problems with electrical components may be the same (after the mileage higher than 200 thousand kilometers without timely change of the fluid and filter replacement) wear-out of channels of linear pressure solenoids. Aisin 6-speed transmissions also have the mode of regulated torque converter lockup slippery, but in contrast to 6НР26-32, here the lock device turns on much later (starting from the 3-rd gear) and have reduced impact on the friction.

Almost all solenoids (in comparison with the valve body in А960) functionally remained unchanged, except for linear solenoids SLU, SLT, SL2 in some modifications. Dirt in ATF damages the valve body and solenoids, therefore cleaning of these components is usually planned as the first stage of the transmission maintenance. During the first years after the transmission release automakers usually modify valve bodies, replace solenoids and change settings of ECM program. Therefore, it is recommended to monitor software changes, which may solve some problems in shifting.Mud accumulation in the valve body and solenoids as well as wear-out of rings lead to lower pressure in the Forward drum that results in premature burning of frictions with steel disks (Forward-C1) and corresponding Forward pistons.

How to repair this transmission (Videos)AB60 Toyota Tundra Valve Body Removal and InstallationToyota AB60E/F Power flowAB60 Valve Body Removal and InstallationAB60F, Code P0983

Instruction manuals and useful linksLink typeSourceDescriptionpdfwww.at-manuals.comSchemewebwww.at-manuals.comScheme AB60Ewebwww.at-manuals.comSolenoid application chartwebwww.at-manuals.comStall testpdfSonnaxValve Body AB60Epdfdrive.google.comAS68RC manual

Transmission general data

The Allison 2000 series includes modifications 2100, 2200 and 2300. This type of transmission was designed for light commercial vehicles operating in sectors of transportation and public transport. These transmissions are equipped with a turbine-driven power take-off mechanism with the N-locking option, and with a parking brake. Transmissions of 2000 series may have up to 6 gears, including overdrive, and be equipped with an advanced electronic control system of the 5-th generation, which provides more efficient operation and more diagnostic capabilities. These transmissions are reliable and highly efficient and can transmit power equal up to 224 kW ( 300 HP) in modifications with narrow or wide ratio coverage. As a rule these transmissions are used for commercial vans, drop-side trucks with a manipulator and all kinds of special equipment with a load capacity up to 13.6 tons ( 3000 lb). These transmissions are installed on almost all brands of trucks, buses produced in Europe (except MAN), Korea, and China. The instantaneous connection between the engine and the gearbox ensure precise modes of operation regardless of the cargo condition and the road quality.

Accurate gear shifting without interruptions of power ensures the best speed characteristics and fuel economy. Fully automatic transmission allows the driver to pay more attention the driving process that is more important in difficult and tedious road conditions. The transmission electronics can be programmed to prohibit the vehicle movement when the auxiliary equipment is used. Consequently, the auxiliary equipment will be inaccessible when the vehicle moves. This feature provides additional security in operation.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type5AT8411410Allison TES 295

Technical issues and repair guidelines

The main repair problems are related to the auxiliary power take-off equipment, torque dividers, and the main one – the cooling process or heat exchanger. Designers of these transmissions quite consciously reduced the transmission resource by means of cooling.

There are 3 main problems related to valve bodies of Allison 1000/2000/2400:

1. Sticking E-shift. When the valve sticks TCM detects that the pressure sensor doesn’t change the status and sets the trouble code P0872- after that the gearbox switches to the failsafe mode.

2. F-trim valve sleeve. The inside diameter of the sleeve wears out, leading to the torque converter clutch surge and trouble code P0741 – indicating the torque converter clutch slipping. . When lock-up stops operating and the P0741 code sets, the torque converter can overheat the ATF, causing damage to the torque converter and rapid deterioration of the ATF.

3. Warped castings. Valve bodies for these transmissions do not have separator plate gaskets, therefore it is required that two halves of the valve body should be flat sanded for protection from cross leakages. In this case locating pins should be removed to flat sand the valve body.

How to repair this transmission (Videos) fluid and filter changeAllison Transmission Assembly

Instruction manuals and useful linksLink typeSourceDescriptionweball-trans.byIdentifying Allison 1000/2000/2400 Valve Bodies

Transmission general data

The

Powerglide is a two-speed automatic gearbox constructed by GM. This gearbox was

mainly installed on Chevrolet vehicles (1950-1973) and on some Pontiac cars. The

gearbox was uncomplicated and extremely reliable, that gained trust of

customers. In spite of its old-fashioned construction Powerglide is still

popular in drag racing (as well as in mud racing) because it is not complicated

and robust.

Technical issues and repair guidelines

The Powerglide is a two-speed automatic gearbox constructed by GM. This gearbox was mainly installed on Chevrolet vehicles (1950-1973) and on some Pontiac cars. The gearbox was uncomplicated and extremely reliable, that gained trust of customers. In spite of its old-fashioned construction Powerglide is still popular in drag racing (as well as in mud racing) because it is not complicated and robust.

How to repair this transmission (Videos)Powerglide Transmission CutawayLEARN TO REBUILD THE POWERGLIDE

Instruction manuals and useful linksLink typeSourceDescriptionwebSonnaxUnderstanding & Overcoming the Powerglide Servo Pin Bias Effect