Last articles

Transmissions info

About transmissions

Transmission general data

The automatic transmission 4L85E was firstly presented in 2001 together with powerful engines Duramax V8 (with torque reaching up to 650 Nm). This transmission was installed only on large SUVs, pickups and minibuses. This transmission is very powerful and can be applied cars which take part in off-road racing, drag racing or custom street driving.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type4ATRWD/4WD65013,6Dexron VI

These transmissions have issues with early style 12 pin harnesses in which transmission fluid leaks around the harness and shorts the pinouts causing transmission to go into "limp mode" (some manuals say "limp home mode"). This issue can be easily rectified by simply cleaning the plug

Which cars run with this gearbox?BrandModelYearTypeEngineChevrolet/GMVAN FULL SIZE 350095-094 SP RWDV6 4.3L V8 4.8L 5.7L 6.0L 7.4L 8.1L 6.5L 6.6L DIESEL

Transmission general data

The 4-speed automatic transmission 4L40E produced by GM found application on the most common BMW 318 (since 1998). This automatic transmission was designed on the constructive basis of a reliable 4L60E, but were produced in Europe for the Bavarian automobile factory. This range of automatic transmissions replaced the 4-speed 4L30E and had been in production until 2007, when GM replaced these transmissions with the 6-speed 6L45. In terms of design the 4L40E (5L40) is the most simple, robust and reasonably priced transmission.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type4ATRWD36095,5-6Dexron VI

Technical issues and repair guidelines

The repair of this transmission mainly lies in the replacement of filter, gaskets and seals (preventing oil leakage), and replacement of burnt friction elements. All parts are interchangeable with 5L40E and 5L50E. Frictions are one-sided as in the popular DP0 transmission. The pack (Direct Clutch; 2nd Coast) burns twice as frequently as other clutch packs.Generally, this gearbox is considered to be reliable and almost “invincible”, when avoiding heavy ATF contamination by friction dust and the abradant which wears out not only friction nodes, but also the valve body.

This issue (oil contamination) often results in self-regulating pump becoming “unregulated”, also remaining in the mode of ultimate capacity. It leads to the rapid gear-shifting as well as to increased pressure in packages resulting in pistons damage. Issues with pistons is a typical soft spot for the 5-speed 5L40E and 5L50E (BMW Х5). The rubber-covered piston (forward) most commonly gets out of order because of its design peculiarities.It is usually recommended to take care about the ATF quality for this transmission.

Which cars run with this gearbox?BrandModelYearTypeEngineBMW3-SERIES00-054 SP RWDL4 1.9L L6 2.0L 2.8L

How to repair this transmission (Videos)Part 1 Transmission ServicePart 2 Transmission Service

Instruction manuals and useful linksLink typeSourceDescriptionpdfshinseiauto.comScheme 4L40E

Transmission general data

The

2ML70 gearbox is a 4-speed rear drive which can be configured in a two or four

wheel drive application. The secret of this transmission lies in combination of

2 electric motors inside the transmission, which serve not only for driving the

car under certain conditions, but also for starting the engine. The 2ML70

transmission has several important advantages when compared to its gasoline

counterparts: reduced fuel consumption, improved performance characteristics,

reduced amount of toxic emissions.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type4Hybrid SystemRWD51512.310.8Dexron VI

This

transmission doesn’t have a torque converter. It is equipped with stop/start

technology and therefore has a 12 volt auxiliary pump to keep the 1-2 clutch

primed any time the engine shuts down. The design of 2ML70 also includes 3

planetary gear sets, 2 rotating clutch packs and 2 fixed clutch packs. The

gearbox functioning is controlled by a Transmission Control Module (TCM) which

is located inside the transmission and the hybrid systems operation is

controlled by the Hybrid Control Processor (HCP) located under the hood.

Which cars run with this gearbox?BrandModelYearTypeEngineBMWX609-14EVT 4WDV8 4.4LCadillacESCALADE HYBRID07-13EVT R/4WDV8 6.0LChevrolet/GMSILVERADO HYBRID/SIERRA HYBRID09-13CVT R/4WDV8 6.0LChevrolet/GMTAHOE HYBRID07-13CVT R/4WDV8 6.0LChevrolet/GMYUKON HYBRID08-13EVT R/4WDV8 6.0LChryslerASPEN HYBRID9CVT R/4WDV8 5.7L HEMIDodgeDURANGO HYBRID9EVT R/4WDV8 5.7L HEMIMercedes-BenzR CLASS09-11CVT R/4WDV6 3.5L

How to repair this transmission (Videos)GM Two Mode HybridWhat is a two-mode hybrid?

Instruction manuals and useful linksLink typeSourceDescriptionwebwww.searchautoparts.comAN INTRODUCTION TO GM'S 2ML70 TWO MODE HYBRID TRANSMISSIONpdfwww.atraonline.com2ML70 (RPO M99)

Transmission general data

The 10R80 is a 10-speed automatic gearbox

designed thanks to fruitful cooperation between Ford and GM (10L90). Both companies

pointed out the fact that while the mechanical part of the gearbox was

developed collaboratively, the software part of the 10R80 will be different for

each manufacturer and, as a result, their corresponding powertrain structures

should not necessarily resemble each other in view of gear shifting algorithms.

This transmission has 10 forward gears, three of which are overdrive ratios.

It's deep 4.69 to 1 first gear ratio is the lowest in its class and it features

a relatively tall 0.63 to 1 final overdrive ratio.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type10ATRWD/4WD80012.98Motorcraft ULV

A built-in electrohydraulic pump ensures that

the "start-stop" feature operates with minimal delay. The 10R80 includes

3 operation modes - "Tow Haul", "Sport", and

"Normal", with each mode changing the gear shifting algorithm and

characteristics to compliment particular forms of driving behavior. Since the

gearbox has 10 forward gears, its running characteristics and, more

importantly, fuel efficiency is maximized by the transmission's capacity to get

a suitable ratio for current operating conditions, such as engine speed, load,

and car speed. This transmission became a standard option for the 2017 F-150

equipped with the 3.5L Eco-Boost engine.

Which cars run with this gearbox?BrandModelYearTypeEngineFordF-1501610 SP R/4WDV6 3.5L V8 5.0LFordF-150 SUPERCREW1610 SP R/4WDV8 5.0LFordMUSTANG1610 SP RWDL4 2.3L V8 5.0L

How to repair this transmission (Videos)10-speed Transmission Assembly

Instruction manuals and useful linksLink typeSourceDescriptionwebwww.f150hub.com0R80 10 SPEED AUTOMATIC TRANSMISSION RATIOS

Transmission general data

3-speed automatic transmission 3HP22 was

produced by ZF company in 1973. This transmission was intended for rear drive passenger vehicles with motors M10, M20,

M30

of BMW product range (big coupes and sedans, 3, 5, 6 and 7 series). This automatic transmission

transmits the torque up to 320 Nm.

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type3ATRWD3202.42Dexron II

Technical issues and repair guidelines

One of the most common sources of problems in this 3HP22 transmission is the governor. The governor is a shifting pressure regulator on the output shaft of the transmission. The gear shifting point according to the car speed depends on the above mentioned governor.The wear-out of niches for plastic rings on the hub of the last transmission clutch is considered to be another soft spot. This problem also may lead to the governor pressure loss.

How to repair this transmission (Videos)3HP22 valve body rebuild

Instruction manuals and useful linksLink typeSourceDescriptionwebwikipediaZF 3HP22 transmission

Transmission general data

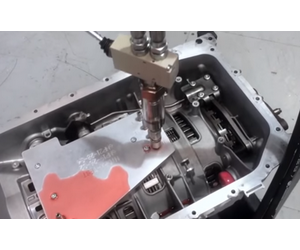

Leak test units allow checking circuit integrity for transmission units through use of hydraulic pressure. These tools guarantee time saving since modern models do not require removal of the transmissions off vehicles. It is a universal machine which merely requires appropriate leak test plate to fit any automatic gearbox. The 4L60 transmission, 4L80 transmission, ZF transmissions are some of the most demanded for this transmission service.

The answer to the question on the reason of oil flowing out of the transmission troubles many transmission specialists. Transmissions oil leakage is in the group of problems with which almost every driver ever found. Under the car there are oil stains that are gradually increased. Set of lubricants is considered to be an important part of the vehicle. Such a problem leads to major failures. Friction of the contacting parts goes uncontrolled, wear debris is stopped from leaving the drivetrain, the assembly doesn’t cool down. It is unsafe and could cause fire.

Various leaks at the junction of gearbox and engine most likely can occur due to the following reasons: wear-out or failure of seals, various defects in shafts and seals, emergence and increase of clearance in the shafts (input shaft, etc.), sealing compound fails to provide the desired sealing, loosening of clamp holdings, failure of properties of seals and gaskets and other effects.

Transmission general data

Dyno stands allow testing complete gearboxes in assembly checking their performance and understand if it is comparable to benchmark characteristics. It is the tool that is certainly needed to provide certified transmission quality. There are options that allow advanced testing of FWD, RWD, AWD automatic transmission vehicles, for both civil and heavy duty models. A dyno stand used to be an expensive option for big-scale car transmission rebuilders but more accessible quality options start to emerge on the international transmission service market.

Why is it important to use a transmission dyno test stand?

What are key components of a transmission dyno?

What is the difference between electric motor and combustion engine dynos?

Principle of operation |

What types of load cells are there in the dynos?

History of transmission dynos on the industry market

Pressure gauges in transmission dynos

Importance of hardware with transmission dyno stands

Importance of software with transmission dyno stands

Major suppliers of automatic transmission dynos

The

transmission of an essential part of a vehicle drivetrain system, transferring

power to the wheels, doing gear switching, distributing load. Depending on the

context, to a large degree term ‘transmission’ is synonymous to ‘gearbox’.

What is the utility of using transmission dyno test equipment?

In the

transmission repair industry, testing of a complete automatic transmission unit

is imperative for large remanufacturing companies dealing with large repair volumes,

is quite desirable for medium-scale companies working widely on the national

level and supplying to other countries, and is a dream for smaller transmission

shops that always do test-on-the-car checks to verify the repair procedure. In

addition, many educational institutions (like tech colleges) need dynos for

proper students’ skill-learning process. Production companies use transmission

dynos in their EOL tests (end-of-line testing).

“Dynamometer”

consists of two words - dynamo (Greek for “power in motion”) and meter (also

Greek for “measurement”). Very often, it is simply called as “dyno”. A dyno

stand used to be a costly tool solely for big-scale transmission rebuild shops,

nowadays, however, more accessible options of these tools are emerging on the

international transmission service market.

One who is new to transmission repairs may actually

wonder: ‘Why a transmission should be dyno tested?’ It is primarily about

warranties and guarantees given by the provider of repair services. A dyno test

ensures that a transmission is performing well and adequately under certain

conditions of operation and this gives a huge grade of certainty that the

transmission will last full life expectancy.

The dyno testing means that you mount a transmission

in the dyno test rig and drive it through various paces. The idea of such

testing is simulation of real-life operation conditions as if it were driven in

the car on the road. At this, the gearbox is taken through a complete set of

operations, with gear and speed switching, and in each gear operation is

performed through the design speed range. Certainly, it is vital to capture

output values, and these are monitored in the test process.

Reputable transmission remanufacturers set their goal

to return the rebuilt product to original factory specifications. With dyno

testing, the following key parameters are checked: torque, temperature,

pressure. Also, operations efficiency is checked and sensor functionality test

is performed. The tech operator is able to verify bolt torque and presence or

absence of leaks in the system. To put it straight, the dyno test assures that

your gearbox operates according to the factory specifications with due regard

to design speed and range of gears.

You need to dyno test gearboxes when:You strive to provide top quality

of your rebuilds.

You want to be sure of the

longevity of warranties that you give.

You want to speed up your repair

processes.

Your partners who contract you in

large volumes need assurance of compliance with highest reman standards.

You value your shop’s reputation

and you want to avoid unwanted returns damaging

Basically, without dyno testing you have difficulty

proving that the gearbox will not fail in operation conditions. Although the

guarantee might have a fault covered, it is your reputation that you need to

protect and avoid frustration when a gearbox is returned back with faults.

What is more, health of the transmission means that no

harm will be done to the drivetrain and no further damage to the engine.

Another vital idea is that a high quality reman transmission can be better

performing than a new factory one. This is important for transmission

performance shops and racing car

workshops.

What are key components of a transmission dyno?

It is important to understand key components of a dyno

test rig as a transmission specialist may wonder how it functions.

Primarily, modern

dynos are fully digital and allow for highly accurate easy-to-perform

repeatable automotive transmission testing. The important factor here is

software and hardware, which is realized in the controller system. These dynos

simulating automotive load conditions are typically quite universal and

adaptable to various modes of wheel drive and automatic transmission types

(including CVT transmissions). In order to cover this universality the test rig

is performed with due regard to capacity requirements, motor horsepower specs,

number of load cells. Let us cover the components of the body of a transmission

dyno.

High-output motor (nowadays it

would be an electric motor)

Load unit (for dynamic loaded

testing). At this, number of load cells is varied for various applications: 1

unit – for RWD (rear-wheel drive) vehicles, 2 units – for FWD (forward-wheel

drive) vehicles, 3 units – for AWD (all-wheel drive) vehicles

Jib crane for transmission mounting

and dismounting

Pumps with hoses to fill and drain

transmission fluid

Pressure sensors

Oil tank and drip trays

Stall brake

Quick release hose fittings

Additionally:

Electric shuttle motors allowing

positioning for different transmission configurations

Tooling kits for transmission

positioning avoiding any potential harm to pumps or certain transmission

components

Bushings for precise transmission

alignment

What is the difference between electric motor and combustion engine dynos?

Modern dynos run on electric motors, they use

electricity stored in batteries and power electromagnets driving axles.

Combustion engines run on gasoline, which

explodes in an enclosed space – it is a well-known process happening in most of

the cars driving on our roads, hence the name. In vehicles, this combustion

moves pistons, which rotate engine’s crankshaft and all that controls rotation

of the vehicle’s axle. This solution is pretty much obsolete and not used in

up-to-date dynos for a number of reasons:

CE has many more parts and occupies

more space (CE with ~2000 parts and EM with ~20 parts). Fewer parts also means

easier serviceability and maintenance.

Disposable fuel with electric

motors, while in a combustion engine, the disposable fuel is gasoline, which

must be carefully stored, as there is a danger of ignition. What is more, fuel

leftovers must be exhausted out of the after combustion.

Electric motor battery packs are

expensive but gradually become more accessible.

With electric motors little energy

is wasted, but with combustion engines quite a serious percentage of energy is

lost along the way. Therefore, it’s the gas-powered vehicle that needs more

energy.

It is more comfortable and

convenient to service an electric motor in a transmission shop surrounding, if

comparing to a combustion engine.

Overall, 75kw (or ~100 horse power) is enough to

drive modern transmission dynos for light-duty and medium-duty application. At

that, electric motors are very much preferred.

Principle of operation

It is

important to distinguish transmission test stands from these two types of dyno

stands: engine dynamometers and chassis dynamometers. With engine dynos, the

engine is removed from the vehicle and installed on the stand by connecting

directly to the flywheel. For this purpose, transmission specialists use

special adapters and it is also necessary to connect the cooling system, as

well as some other components - this procedure takes a lot of time. Engine

developers and manufacturers mainly use these stands.

Chassis dynos allow for testing of the vehicle

as it is driving on the road, fully assembled. These are rather popular among

people doing racing cars or performance vehicles.

Transmission

testing stands are suitable for both transmission manufacturers and

transmission repair service shops. During testing of complete gearboxes their

performance is compared against benchmark characteristics. Multiple readings

are taken using corresponding sensors and transducers, their readings are

converted to visually explicit and perceivable information. Obviously,

transmission dynos vary in their design to cover FWD, RWD, AWD automatic

transmission vehicles, support and fit civil light-duty and/or heavy-duty

models. Precision alignment tooling and data acquisition & control systems

play an important part in quality transmission testing.

What types of load cells are there in the dynos?

Dynamometers are classified by the method of creating

a load. Nowadays, the accepted brake standard in a transmission dyno is eddy

current brakes.

EC brake is an electrically controlled brake with air

cooling. In it, load is created by inducing a magnetic field in a rotating

disc. Heat produced by the rotating disc is dissipated in air. Moving parts are

stopped by EC brakes with the help of drag force. These brakes are a great

option for lower power applications and dynos up to 250 hp.

Water brake works on the transfer of water momentum

creating load on the tested unit with the absorbed power heating water.

Usually, these consist of a turbine / propeller, which is mounted in an

enclosure with water. Water brake are for high power applications far over 250

hp. Largely, for engine dynos with thousands of hp.

Alternating current dynamometers are another option

which is less frequent when compared against EC’s. These are used for engine

dynos and the idea is in mimicking the load placed on the engine as it powers

vehicle.

History of such equipment on the industry market

Transmission

testing equipment has a particular history in the USA, the leader of car

industry. The world’s largest manufacturer for this type of equipment –

PowerTest – is located in Wisconsin. They started in 1976 and grew to acquire a

large number of brands and companies from the industry. Nowadays, PowerTest

owns such brands as AIDCO, Axiline, Hicklin – all of them shall be known to

people who spent decades in the transmission industry.

Another

well-known US manufacturer is MAE (Mustang Advanced Engineering) who were on

the market since 1970’s as well. As of today, they provide a system for testing

automatic passenger car and light truck inline and transverse transmissions as

well as systems for medium- and heavy-duty applications.

There are

some other companies located in the USA but they are far less active and less

known to a global audience, as of today.

Although, dynamometers have been around since as

far as the 18

th century, quality transmission dyno options are not

as many as one might have thought.

In the 21st

century, USA are not sole prominent manufacturers and they need to compete with

companies like RayTech from China or Hydra-Test from the UK for the global

buying audience.

Pressure gauges in transmission dynos

In previous decades, the equipment output gauges were

analog but nowadays there is obvious tendency for digitalization. With modern

control systems, the process of running through gears and checking electronic

solenoids is automated. One single system runs many different vehicle and

transmission types.

If a transmission stops working because of a sensor,

harness, connector or solenoid, it will be visually shown on the screen,

explicitly as to identify this failure. Comprehensive data on each sensor can

be compared against the benchmark result and thus it will be easy to determine

whether that particular sensor is good or bad.

Multiple fluid

pressure gauges enable thorough shift timing evaluation and adjustment.

Controller box ordinarily comes for 8 pressure sensors with quick fit

connectors. This can be expanded to 2x times (total 16 pressure sensors) if

this happens to be required in the technological process. Readout in modern

dynos is easy to adjust for any needs – especially if the software is

appropriate for client-specific demands.

Importance of hardware with transmission dyno stands

Modern

advanced dyno stands allow control and full testing of electronically shifted

Mechatronic gearboxes and valve bodies. The importance of hardware for such

dynos cannot be understated.

Modern dyno

stands provide complete computerized control and with that extremely precise

test procedures are easy to repeat. Some companies like Axiline concentrate on

the US domestic market. However, the range of supported gearboxes is typically

large: the dynos fit most USA home and non-national RWD, FWD, transverse, and

Continuously-Variable Transmission gearboxes. These dyno stands check:

gearbox

line pressure,

TC

lockup and downshift,

shift

point and response,

stall

speed, and more.

At this,

emulated load conditions for vehicles are applied and speed and load are

measured with potentiometers. Transmission rebuilders will be able to

confidently spot ATF and pressure leakages, check controls of the systems and

hydraulics, and perform minor corrections with the gearbox still being mounted

on the tester.

Reliability

of hardware and flexibility of software are equally important for efficient use

of transmission dynos.

Hardware is

the brain of a transmission test stand. You do not have to be an IT-specialist

to know to value enduring components that will serve to last for years and that

will be protected from any electric malfunction.

In many

cases, a physical body of the transmission dyno is still able to last for

years, however, the hardware or the controller itself is very obsolete and

cannot meet demands of those new development that have come by recently. When

looking for such an advanced tool, it is also vital to look into this aspect of

the equipment – how is it going to be supported after a couple of years of

operation.

For

instance, the most-professionally done Chinese dynos are looking really good,

but the hardware part here is just a contribution and doesn’t bear any

advantages. Axiline (at PowerTest) has quit updates for their controller system

and just go with what had been on for many years now.

A good

option to look into are companies that supply controller systems separately

form the dyno testers. This means that they are concerned about all the aspects

of the equipment: physical, hardware, software – and can deliver a lasting

product. Hydra-Test’s HTC-S is adaptable for existing dynos from former years. If

the machine has served years and is still functioning well, it can be easily

refitted with a new controller box – enhancing the functions and data

validation and processing.

For instance, among

transmission dyno users from the USA and Europe there is often a situation when

their current system is obsolete and shows the following deficiencies:

Difficult process of programming new units.

Inability to smoothly ramps solenoid current.

No support for newer developments that came into market after 2020.

Absence of reliable tech support from the manufacturer.

Current transmission controller being no longer in production.

A new

controller generation tackles these issues quite successfully and relatively

easy. If you happen to be negotiating with a particular company’s manager, ask

all of those questions upfront. New controller systems ideally have to come in

a modular format when it is possible to build up a controller from several

modules facilitating the support and any future upgrades.

New units

coming to the market can be controlled efficiently with adaptability and

flexibility of software. Ask your supplier if it is possible to write your own

test scripts, this feature may be hidden but is pivotal for efficient use of

transmission dynos.

Interpolation

feature allows for solenoid ramp up, and with ease. New developments like

Mercedes 722.6 or latest Chrysler models (like 68RFE) are supported equally

with older designs.

Technical

support is pivotal here. You do not want to be stuck with a fault that your

supplier cannot be resolved for you. Large transmission equipment companies or

companies coming from non-European countries oftentimes have these issues.

As an

important note, remember that mechatronics have a different testing method and

a 3

rd party supplier of equipment cannot have OEM access codes.

Their use is restricted and protected. Therefore, do not expect that your

transmissions can be tested along with their mechatronics components. It is

simply not the case.

Mechatronics

are excluded from the testing circuit with universal transmission dynos. They

are tested separately by individual OEM tools – like ZF Testman and the like

for other OEM’s. Double- or triple-check it if your potential supplier promises

to supply mechatronics testing with their equipment.

Importance of software with transmission dyno stands

The IT field is on the rise and its advancements have

also concerned the pretty much conservative transmission repair industry. When

considering a transmission dyno, check for the following factors:

Date of software release

Frequency of software updates

Ease of update installations

Presence of online tech support

Possibility of desk sharing

sessions (for example, via TeamViewer)

Flexibility of operational

algorithms and their adjustments to clients’ needs

Convenience of output data readout

and printing out

Attractive and user-friendly design

In fact, the software factor oftentimes goes without

notice but it plays an essential role in efficacy of the dyno system. Just

imagine running your high tech tool on Windows XP when it is 2020’s. This

discriminates the whole investment.

Major suppliers

Nowadays, it

is easy to commerce internationally and the suppliers are not limited to their

local markets. US companies supply to Europe and to Turkey, Chinese suppliers

have clients in the Middle and Near East. European suppliers have clients all

across the globe – from Mexico to New Zealand. A certain group of suppliers

works chiefly for the post-USSR countries.

1. Power Test

Active

since: 1970s

Location:

Wisconsin, USA

Types of

equipment supplied: transmission dyno test stands, engine dynos, chassis dynos,

valve body test stands, torque converter repair equipment, and other (all via

different brands – Axiline, AIDCO, TCRS)

About: on

the market for over 40 years, Power-Test has been providing test equipment to both

manufacturers and rebuilding facilities and distributors in various field of

industry. These include mining, oil & gas, power generation, and

particularly military applications, marine, and construction.

Product

updates: not recently.

Power Test

has been acquiring local USA companies under one hood and is the largest

company producing these types of products in the world. At that, the most

powerful products are by AIDCO as they are for military applications. Test

stands for transmission shops come as contributing to overall Power-Test

profile.

CHECK OUT

PRODUCTS

https://go4trans.com/superflow-dynamometers-and-fl...

2. RayTech (Guangzhou Ray Technology Solutions)

Active

since: 2010s

Location: Guangzhou,

China

Types of

equipment supplied: transmission dyno test stands, valve body test stands,

torque converter repair equipment, and transmission parts.

About: Some

Chinese suppliers cannot be counted on, simply because of how they present

their product. RayTech is different in these terms although their web presence

is also a little unclear to a European or American potential buyer. They also

take part in certain expos across the globe.

Product updates: new test plates for RayTech

equipment.

Raytech is

probably a most recognizable supplier of transmission equipment (along with a

Chinese company TranSpeed). Despite having a good portfolio and attempts to

position their products, some proper online presence could be improved. This

supplier may be best to be contacted via Chinese local trading platform.

3. HYDRA-TEST

(Cottingham Engineering LTD)

Active

since: 1990s

Location: Kettering,

United Kingdom (head office) / Minsk, Belarus (daughter production company)

Types of

equipment supplied: transmission dyno test stands, valve body test stands, torque

converter repair equipment, valve body repair tools.

About: at

this day, Hydra-Test is the only prominent and reliable transmission repair

equipment supplier from the United Kingdom. In 2019, the company opened a

subsidiary production office to be more competitive in terms of product

production cost and be able to deliver most reliable support quality. Valve

Body testers by Hydra-Test are known for durability and full coverage of

clients’ demands. Hydra-Torque equipment fabricated in the Belarusian division

since 2017 has been supplied to various countries, including a heavy-duty

application. The team is also open for custom-built solutions and delivers them

in exact match to clients’ needs.

Product

updates: Hydra-Dyno (launch of transmission dyno production), HTC-S (newest

controller generation), 0AM valve body test tool.

ThisUK

supplier is well-known for their attitude, constant update of available

solutions. Opening a production site in Belarus is also an advancement. Some companies

from post-Soviet territories can be barely counted on. However, if guided by

European service standard, it is a great combination of affordable price and

highest quality of transmission repair.

CHECK OUT PRODUCTS https://go4trans.com/hydra-torque-transmission-dyn...

4. Mustang AE

Active

since: 1970s

Location: Ohio,

USA

Types of equipment

supplied: dyno test stands for a huge variety of applications (including

transmission dynos), solenoid testers.

About: on

the market for over 40 years this company has launched a series of equipment

for various applications, including military sector, heavy-duty equipment, and

more. The company aspires to deliver creative thinking to drive continued

success. They are one of the leaders in delivering sophisticated dynamometer

technologies and advanced engineering capabilities.

Product updates: not recently.

Mustang

AE’s growth has been hindered recently but it is a supplier worth referring to

at least for comparison. A company with such a serious portfolio that includes

emission measurement system fabrication, own design services bureau and more is

certain to work on transmission repair clients’ requirements in a diligent way.

5. Extra:

We tried to contact alternative Chinese and USA suppliers to provide more info for consideration here but were treated with silence or an awkward invitation to come to China to see the machine and learn about pricing.

How to repair this transmission (Videos)RockAuto Auto Parts transmissio being dyno testedG-TEC: transmission dynoPowerglide On The DynoTransmission dyno upgrade with Hydra-Test HTC-S controllerTransmission dyno at Certified TransmissionsG-TEC: DYNO Transmission Tester for "light" vehiclesHow your Transmission was Dyno TestedSupeflow. Axiline transmission dynamomenter

Instruction manuals and useful linksLink typeSourceDescriptionpdfhttp://promand.com.auAXILINE 66K TRANSMISSION DYNAMOMETERpdfSuperflowAxiline 97000 dyno brochurepdfPowertestPowertest transmission dynos. Product brochurewebMAEMustang MAE transmission dynoswebGearstarWas your traansmission dyno tested

Transmission general data

Balancing is used after all components have been replaced and subsequent welding is done. The process of balancing allows transmission service people to find out if there is a bad or uneven weld on the circumference of a Torque Converter. If it is identified, the operator can easily weld on a small amount of material or remove it. Performance transmission and racing transmission specialists pay special attention to Torque Converter balancing.

When you turn the ignition key the Torque Converter starts to rotate together with the engine. Torque Converter of about 250mm in diameter and of about 10 kg in weight imbalance in its RPM can cause such a serious vibration that the entire vehicle will be affected, including fastening elements of the engine and the automatic transmission.

Balancing machine for torque converters allows us to check imbalance of this element with guaranteed accuracy. Precision system implemented in these machines allow transmission repair experts to pinpoint exact place of excessive or insufficient weight.

Transmission general data

The Vacuum Test Unit is used to test the vacuum integrity of all Valve Body hoses and valves. This method of Valve Body testing is considered to be quite a traditional testing solution for transmission shops - it is a money-saver which does a straightforward job. At the same time it doesn’t provide the many advantages of the modern sophisticated transmission service tools. Vacuum tester is often used jointly with a Valve Body test equipment for remarkable results.

The vacuum test allows to evaluate the condition and wear of the valve (plunger) in the body of the hydraulic unit. A worn valve or a hole in the hydraulic unit may result in improper operation, reduced performance or malfunction of the automatic transmission. In most cases, it is possible to assess the wear of the hydraulic unit of the automatic transmission without the vacuum test. However, if you have repaired hydraulic unit with the help of special reamers and valves produced by such manufacturers as Sonnax, a vacuum tester is a must because the vacuum test allows you to quickly and easily test for leaks in the channels of the hydraulic unit.

Transmission general data

Many Valve Body problems are due to solenoid issues. Typically, a Solenoid tester is similar to a Valve Body testing unit - it is offered by the same manufacturing companies with similar software and hardware changed to do job only on Solenoids. It comes as an efficient solution to smaller-scale transmission repair businesses looking for a more affordable solution to improve their Valve Body rebuilding quality and general automatic transmission rebuild standards as well.

Solenoid testing machines are used for checking the state of solenoids produced by different manufacturers of automatic transmissions. Separate solenoid test blocks make it possible to run tests for the majority of most popular makes on the actual international market. Modern Solenoid Test machines now typically come as a universal model and allow to cover any transmission specialists’ preferences in transmission rebuilding operations.

Modern Solenoid Test tools allow possibility to run tests at maximally high required temperature and solenoids are tested as they function with the valve body, as originally designed. The automatic transmission solenoid is an electromechanical regulator in the gearbox, in response to the computer impulse it opens or closes the channel in the hydraulic unit to control flows of hydraulic fluid. Solenoids control the hydraulic switching of operation modes in modern automatic transmissions, CVT and DSG. The solenoid is inserted in the channel of the hydraulic unit and is fixed by bolts (or a pressure plate) and at the other end through the plug of the wiring harness it is connected to the electronic control unit of the automatic transmission.

How to repair this transmission (Videos)RayTech Tester for Transmission SolenoidHydra-Test Solenoid test machine guideTransmission Solenoid Testing (Ohms Law)Automatic Transmission Basic Solenoid TestingHow to test automatic transmission solenoid status: OK or Bad ?Hydra-Test HT-SOL 25 - IntroHow to test a Transmission Solenoid

Instruction manuals and useful linksLink typeSourceDescription0Gears MagazineTransmission Solenoid Test Methods0Gears MagazineUnderstanding GM 6T40 Solenoids0Gears MagazineSubaru Lineartronic CVT Lock-Up Solenoids0Gears MagazineFord Solenoid Strategy Numbers: Is It Necessary to Program?

Transmission general data

In the automatic transmission, the valve body serves as the hydraulic control center responsible for gear shifting and torque converter clutch application. Inside a valve body, one will see a maze of channels, different sets of valves, and a variety of solenoids. These all work together controlled by the transmission control unit or module (TCU or TCM) to direct hydraulic fluid through these passages to the valves activating the required clutch pack or servo to apply or release these elements causing gear changes and torque converter clutch application. Modulation of the components is what provides smooth gear changes over the range of throttle application or driving conditions.

Why is valve body testing important and necessary?

Valve body

testing covers a significant range of tasks. Among these, one may distinguish 5

principal ones as below:

Speed up the process of repair of a worn valve body,Be able to pin-point a source of malfunction within a valve body,Provide confidence in valve body repair for extended warranties,Be compliant with stringent quality requirements,Provide end-of-line testing for a new valve body as a factory product and performance valve body testing.

The only other viable option to test a valve body is to test-in the vehicle, which involves a large amount of labor and technician time especially on newer vehicles where installation and removal of the valve body may require other vehicle components to be removed to gain clearance. Simple remove and reinstallation of a valve body inside a car can take up to 4 hours to complete. If a shop is specializing in transmissions and valve bodies and repair volume is low, this might be an option that works for them, but most shops are competing on price and so the required technician time make s this an expensive option. The real issue with this method is when there is a fault or malfunction that is not obvious and the technician has to perform the install, test, remove, and repair procedure multiple times to try and identify the problem or worn circuit in the valve body. If a shop has any significant volume of transmissions to repair, the technician and owner simply do not have the spare time to do this and needs to avoid time-consuming troubleshooting road tests.

Subsequently, conventional scan tools and pressure gauges do not always suffice to determine what exactly is causing the trouble within your valve body, especially if it has significant mileage. An inexpensive vacuum tester is certainly a must-have for a quick bench test upon tear down. It serves as a cornerstone every time one starts valve body inspection and repair. A vacuum test can identify a worn valve or questionable circuit, but it may be difficult to determine the degree to which a valve, or a bore, is worn and it may not identify the wear as clearly as needed. A valve body tester emulates road conditions and actual hydraulic operation of the valve body in all gear ranges as well as near the normal operating temperature of the valve body. The valve body can be tested at a variety of pressures with temperature control and strict control of solenoid amperage to simulate the hydraulic modulation as gear shifts occur. The performance of the unit under test can then be compared against benchmark data in a graphical or tabular format. This allows a technician to identify faults or questionable data that are not able to be seen in the vehicle. The modern valve body test is a complex and eloquent tool that gives the technician the ability to identify the exact source of trouble, leaving little room for doubt and giving confidence that the repair has been performed correctly.

The ability to provide extended warranties and to keep warranty claims as low as possible have a direct effect on the reputation of a shop. In order to be confident in the repairs to offer these types of warranties it is important that the unit is thoroughly tested using consistent test practices. A shop with high warranty claims, even if addressed and the issues rectified, can suffer from unhappy end customers and this can have a direct effect on the reputation of the shop. Therefore, if one is concerned about delivering the transmission shop’s valve body repair guarantee and protecting the shop’s reputation, quality valve body test equipment is crucial.

Another important factor is compliance with certain requirements for a repaired product. This comes into play if a shop or remanufacturer enters in a contract with larger companies providing multiple repaired or rebuilt units. This is common in fleet accounts where the removal and installation of the transmission is not done by the shop remanufacturing the unit. When doing this kind of work there may be a requirement that repaired or remanufactured units meet a certain quality standard (confirmed by thorough testing).

One more application for advanced valve body testing is end-of-line testing. This is typically larger remanufacturing companies or even OEM that need to make sure that the unit just built is performing as per the specification and there has been no fault during the production process. This can also include performance shops that build valve bodies for racing or for heavy duty / towing applications. The volume may be lower, but the use of a valve body tester is critical in these operations as well.

History and principle of operation of a transmission valve body tester

Valve body test equipment started to become common among transmission repair shops in the early 1990s as valve bodies transitioned from hydraulic cast iron three speed units, to aluminum electronically controlled four speed units. During this pre-digital era the equipment was fully analog with multiple pressure gauges to show readings and even lights with pressure switches to show if there was a minimum amount of pressure in a circuit.Valve body

test equipment has started to gain among transmission repair shops of various

scales back in 1990s and during that pre-digital era the equipment was,

obviously, fully analogous with multiple readings shown on the external gauges.

At that point, the principal components of a valve body tester were the machine itself (mainly a pump and pressure regulation system, the corresponding test plates connecting the test unit to the machine and gauges, and a basic shift controller that would fire the solenoids on or off to achieve each gear). An operator would need to watch the gauges upon a gearshift and make a determination on the quality of the unit based on experience. Nowadays, the data acquisition and processing controller integrated into the testing process plays the key role in modern testing. At that point, the pivotal components of a valve body tester were the machine itself

and the corresponding test plates connecting the test unit with the tested

element. Nowadays, the data acquisition and processing controller integrated into the testing process plays another vital role. Here we may have a close

look at all the three key elements that were specified.

If we break down the key elements for modern valve body test machines, we can see there are three key areas:

1) The principal components of a modern Valve Body testing machine:

The hydraulic pump and motor,Suction and high-pressure filters,Input and output pressure transducers,Heating elements and temperature controllers,Proportional and gate valves,Oil tank (to be filled with automatic transmission fluid),Integrated personal computer or a portable laptop.

Based on this list, the idea is that the system feeds ATF into a valve body under varying pressure and temperature conditions. These would vary to emulate real-life driving conditions.

2) Valve Body and Solenoid test plates

and adapters

These adapters emulate the case connection for a valve body or the bore in a valve body for a solenoid and allow the unit to be connected to the test machine. Connection test plates may have orifices for compatibility with certain valve bodies and plumbing to closely emulate how fluid is fed in the vehicle. Connection hoses and cables differ depending on the model. Typically, plates and cables are model specific and it is one test plate and one cable for a certain model of valve body.

3) The control system to drive solenoids and data acquisition for recording and presenting test data.

With the advent of modern valve bodies coupled with mechatronics units, the task of powering and controlling solenoids is not getting easier or less critical. As there is currently no universal tool to test mechatronics components (link: https://go4trans.com/technical-valve-body-articles/advanced-hydraulics-testing-for-valve-bodies-why-there-is-still-no-universal-solution-for-mechatronics-assemblies/), valve body testers are designed to universally test the hydraulic parts of these valve bodies. With modern units, PWM solenoids require a special approach that is vastly different from ON/OFF solenoid testing and for this purpose more complex controller systems and software are required.

Data acquisition is much more crucial with testing of modern valve bodies. The ability to capture data at 500Hz-1000Hz is necessary to comply with up-to-date valve body testing standards. With 500-1000 reading per second, one can be sure that no data will be missing, and the valve body or solenoid faults will be easy to identify.

The acquired valve body data is then compared against benchmark data previously store in the system. This is done via graphical overlay of the tested performance data. With a visual graphical display pin pointing faults can be done quickly and easily.

What types of valve bodies can be tested?

Modern valve body testing systems are built to be universal and are suitable for transmission repair shops across the globe. The testing process itself does not change from a valve body to valve body. All units are tested hydraulically, and solenoids are checked electrically. The necessary part is that the manufacturer has to be able to provide a valve body test plate suitable for a new / particular valve body.

There are a few aspects of testing for various valve bodies worth touching on separately:

1) Latest model Valve Bodies with mechatronics, or TEHCM testing (for a thorough review, read the article: https://go4trans.com/technical-valve-body-articles/a-good-closer-look-into-mechatronics-units-testing/)

Generally, the mechatronic part is omitted from the testing circuit. There are 2 key reasons for this. Firstly, there is no universal tool that can test all varieties of TEHCM applications. Secondly, a transmission specialist really wants to test all parts separately – to be able to identify the valve body fault most clearly without questioning if it is a valve body or a TECHM programming/fault.

Power Test’s Axiline has a solution to test just a few types of TEHCM applications with their WinDyn Test Cube system. There is number of limitations with this system as the system can only test:

-6HP19, 6HP21, and 6HP26 mechatronics by ZF but not all types of these models (with exclusions by years),

- some GM (General Motors) models: 6L45, 6L50, 6L80, 6L90, 6T40, 6T45, 6T70;

- DQ200 (0AM) and DQ250 (02E) among DSG’s.

Another concern is whether this solution is worth the investment as the Test Cube by Axiline is nearly as costly as the valve body testing machine itself. The standard solution is to use corresponding TEHCM tools by OEM’s – like ZF Testman for ZF.

Other manufacturers of valve body testing equipment have omitted the mechatronic part from their test cycle.

2) Solutions for Valve Bodies popular

in all countries across the globe

Axiline specializes in the USA market and concentrates on the models that drive on the North American roads: GM, FORD, Chrysler, and Allison. For example, the Axiline solution line for GM is widely used globally on popular models such as 4T65-E, 5L40E, and 6T40/45. Some of the supported models are most common in the US becoming quite old – for example, 200C, 400. Concentration on the USA models is not surprising as the USA car market is the largest world market – however, this leaves transmission repair specialists from other countries of the world not covered.

Raytech or Transpeed, which are China-based, offer solutions based upon models popular on the Chinese roads - although they trade globally and strive to provide solutions across the globe.

Hydra-Test has opted for universality and the solution that covers all of most popular models globally and locally: German valve bodies by ZF and VW; American valve body models by Ford, GM, and Chrysler; Asian transmission valve body models by Hyundai, Kia, Toyota, Nissan, and more.

Kinergo’s Valve Body test machine, an emerging solution from the advanced post-Soviet industrial region, is covering what is in demand and the team provides solutions inspired by other manufacturers.

3) Continually adding new testing adapters and solutions

As a repair technician needing to stay current with the ever changing automatic transmission repair market one would want to invest in a tool that will be on pace with the trends, model updates, and new models of the industry. Therefore, it is vital that the likes of the 9HP by ZF, AC-60E by Toyota, 8 speeds by GM, the 10L by Allison, or latest CVT’s like JF016 are being added to the range of solutions by your supplier of automatic transmission repair equipment.

4) Custom-built solutions

If you are developing your own valve bodies or if you are producing performance valve bodies, it is necessary that the manufacturer of your equipment knows to handle solutions that are demanded by your company. A need for personalized valve body testing can be met with reluctance to take it on or a high cheque. However, for some manufacturers this is a good cause for faster introduction of newly-launched valve body models to their product range. For instance, this is how Hydra-Test took on heavy duty solutions: although the company specializes in the models for light-duty civil vehicles, they have introduced VOLVO CE (Construction Equipment) PT2116-PT2509 and PT1860-PT1861 as there was a demand for this.

How do valve body testers check individual solenoids?

Generally, valve body testing equipment allows for solid verification of solenoid operation. The technician can see how solenoids installed in a valve body perform in the valve body assembly. Here we shall focus on how valve body testers can be used with solenoids separately from the valve body.

If a transmission repair specialist is just beginning to repair and remanufacture their own valve bodies, they may opt for a solenoid tester and valve vacuum tester combination. A vacuum tester is conventional inexpensive tools – Sonnax vacuum tester is the option of preference.

There are several methods of solenoid testing but a most thorough check is with implementation of advanced solenoid testing equipment (check the solenoid testing equipment section). The question comes up on if a transmission technician has to have separate solenoid tester and valve body testing machines? The answer really depends upon the volume or work a shop has. If you can split the time needed to test solenoid and valve bodies on one machine then there are solutions to test both in a valve body tester. However, if the volume becomes such that testing solenoids holds up being able to test valve bodies, then the shop is really in a position of needing two separate machines.

The option of testing solenoids with the valve body testing equipment makes sense when you have lower volumes of work. This feature is easy to add as by default the hardware, software and the controller of a valve body testers is more advanced than that of solenoid testers. They only step needed is addition of solenoid testing blocks with a valve body tester so inquire if your potential supplier has the ability to easily add this feature to the valve body test machine.

Here is an example of the UK’s Hydra-Test add on adapter package for solenoid testing on their VBT Deluxe. A solenoid adapter plate is placed in place of a typical valve body pate and their line of solenoid test blocks fit exactly as they do in the solenoid machine. The solenoids can now be checked hydraulically and electronically with all the same quality of data capture and processing as the valve body testing.

Importance of hardware with transmission valve body test stands

Hardware plays crucial role in reliability of the testing equipment and certainly contributes to having the equipment up to actual standards as time advances. The are many internal components that serve to capture and process transmission valve body operational data. These are the pressure transducers, power supply, transducer distribution board, cabling kit and leads, temperature controller, and so on.

The hardware serves as the control center of a valve body test system and it is the key of valve body performance data processing by using pulse width modulated solenoid outputs, analog inputs, discrete inputs, frequency inputs, analog outputs, temperature sensors – as key data acquisition components.

Most often, suppliers of testing equipment develop and apply their own hardware unless there is a need for some specific solution. An example of past cooperation between companies in the industry was Mustang Dynamometer and PCS (Powertrain Control Solutions). PCS controllers were private labeled for Mustang as a means to support a large variety of transmissions in the mid-2000’s for their tests at the time. However, cooperation between a few parties in not a strategy to last long enough and the best approach is using own solutions.

Hydra-Test has brought the controller development in house with their initial release of their HTC-K controller and more recently the HTC-S controller. This is the latest controller capable of valve body and transmission testing. The hardware components here are built to last with extra protection and convenient modular system, so the system can grow as a customer needs more capability and/or as new units are added and need to be tested.

How to repair this transmission (Videos)Answermatic Valve Body Test machineKinergo Valve Body Testing machineHydra-Test Valve Body test machine guideHydra-Test Valve Body test machine overviewHydra-Test 0AM (DQ200) valve body testing on a benchZF 6HP19 - valve body testing on Chinese machineValve body testing explained A6MF valve body testing on Chinese testerVacuum testing with Sonnax toolsATS Diesel Valve Body testing on a bench

Instruction manuals and useful linksLink typeSourceDescriptionwebBuy Hydra-Test Valve Body tester

Transmission general data

The family of automatic transmissions V4A11 - V4A12 for 4WD (RWD- R4A11) drive of Mitsubishi Pajero Mini was designed by the AT (automatic transmission) department of Mitsubishi in 2000 simultaneously with FWD versions F4A11-F4A12. The difference between V4A11 and V4A12 is in slightly higher transmitted torque, but both versions use the same engine (0.7 liters). The 1-liter engine can be used only for F4A12 or R4A12 (AWD- V4A12). The V4A11 \А12 unit is mainly installed on AWD versions of Pajero Mini for a

Japanese market. These transmissions were aggregated with a minimum

4-cylinder engine (0.7 liters) The design of all sub-modifications

is quite similar, equally reliable, and this transmission goes so long that the cost of the machine

at the time the overhaul of the machine becomes comparable to the cost

of the bulkhead automatic transmission. The gearboxes were adapted for

different engines and different underfoot spaces of the Mitsubishi

mini-cars from (eK WAGON to Pajero Mini).

Number of gearsTransmission TypeDriveTorque (Nm)ATF (full capacity) LATF (change) LATF type4ATFWD/AWD3,52SP III

Technical issues and repair guidelines

The repair of these transmissions mainly consists of replacement of the filter and change of the transmission fluid.In most cases, the reassembly of the transmission, cleaning of the valve body and replacement of solenoids are performed by car owners. In many cases, the replacement of this automatic transmission with the used one turns out to be less expensive than its repair.